Virtual Reality Training

Whats is Virtual Reality (VR)?

Virtual reality (VR), also referred to as Immersive Multimedia or Computer-Simulated Reality, replicates a real food processing or manufacturing environment visually for a trainee to observe and learn from.

So how is Virtual Reality (VR) used as an additional tool in training?

By downloading a customised video file to a smartphone and pairing it with a simple headset, trainees are able to be transported into a learning scenario with a 360° view of the context.

What is the VR experience like in simple terms?

In simple terms, the ‘virtual’ part means, if a trainee with a head set looks up, left, right, or behind them, they can see the whole 360° environment they are in, while observing the training content and instruction.

How can VR as a technology be used in Food Manufacture and Operations?

Virtual reality (VR) is ideal for standardising operating procedures (SOPs), getting contractors, and new inductees on the same page quickly, and to assist less experienced operators to learn from their more experienced peers.

A sample of how Food Safe leads the market with innovative solutions and VR capability:

Can VR actually help clone your best operators and how they undertake a procedure?

Yes, absolutely! You can literally clone your best staff’s skills and get the other operators to replicate them when it comes to a particular SOP, boosting operations and the standardisation process.

Virtual reality allows Food Safe and companies we partner with to deliver complex or technical skills and learning in an easy to understand smart way that operators can identify, familiarise themselves with and most importantly have a better chance of remembering and applying!

What are the advantages of virtual reality training in manufacturing operations?

These include the following:

- VR training gives you the ability to simulate dangerous or risky situations within a controlled environment.

- VR allows you to train to accurate and realistic simulations in operations and manufacture, while simultaneously delivering technical product safety content.

- It allows you to cater for large numbers of operators /trainees over various locations/shifts

- VR training allows you to deconstruct complex tasks into manageable easy to understand visual steps (EG CIP, line change-overs, dismantling, and assembling equipment).

- VR training cost effectively allows all operators to visualise jobs such as control room checks, preventive maintenance, line or product changeovers, cleaning tasks, and go on to replicate the learning more easily.

In short, VR is one more effective tool to add to your kit of training options!

What are the advantages of collaborating with Food Safe on a virtual reality (VR) training project?

- Being an early adopter and having immersed ourselves in the technology for a while, with working prototypes and training modules we save companies the time and resources that would result from starting from scratch.

- We have built a partnership with global leading VR production teams and transfer the resulting network and best practice immediately.

- We bring our highly rated and unique skills with embedded literacy and adult learning skills to projects we collaborate with. This maximises the effectiveness of the training media while minimising costs.

- Based on our experience we can advise companies where the technology works and how to make ideas you have on where to use the technology, work, further optimising the impact of a project.

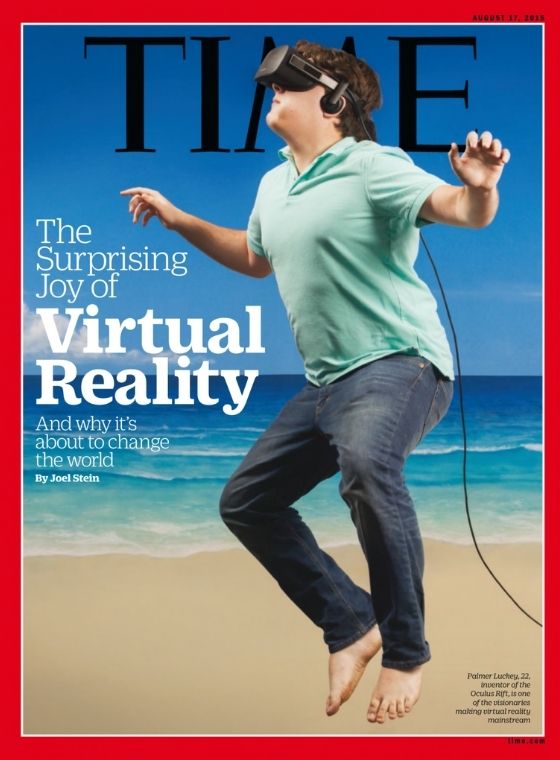

- We are experts on how to link VR into NZQA qualification standards and the brand new, highly rated New Zealand Certificate training. Keen to know more? Food Safe offers customised solutions in food safety training and auditing; to suit specific company needs. Call us on 0800 003 097 or email us at [email protected] for all food safety training needs. Here’s what Time Magazine has got to say about Virtual Reality technology:

Keen to know more?

Food Safe offers customised solutions in food safety training and auditing to suit specific company needs. Call us on 0800 003 097 or email us at [email protected] for all food safety training needs.