About HACCP

Here’s an introduction to HACCP

HACCP stands for Hazard Analysis Critical Control Point

HACCP has its origins in the NASA space programme and was further developed by the Codex Alimentarius Commission as a methodology and food safety risk management system. It is used to identify, prevent, and proactively control food safety hazards.

What are some of the basic definitions?

Food Safety Hazard: A biological, chemical or physical agent in, or condition of, food with the potential to cause an adverse health effect.

Food safety hazard analysis:

A food safety hazard analysis is done in order to determine which potential hazards need to be controlled, how much control is needed, and which combination of control measures should be used in order to make sure that food is safe.

Supporting Programmes / Good Manufacturing Practice (cGMP):

A production and testing practice that helps to ensure a quality product. Basic preventive guidelines for plant and facility operations. Guidelines aimed at food processors aim to include all HACCP methods and procedures and typically address

- Plant design and construction material

- Water supply

- Plumbing and toilet facilities,

- Equipment and utensils

- Raw food handling and testing practices

- Personal hygiene

- Pest control

- Waste disposal

The slides explain how GMP and Supporting Programmes support HACCP:

Some more HACCP terms explained:

Risk analysis:

A process consisting of three interconnected components: risk assessment, risk management and risk communication.

Risk assessment:

A scientifically based process consisting of four steps

- (i) hazard identification

- (ii) hazard characterisation

- (iii) exposure assessment and

- (iv) risk characterisation

Verification:

Act or process of establishing (confirming) the accuracy or existence of something; in the quality field, verification is a systematic, objective, and documented process of confirming that a product or service conforms to various requirements (customer, regulatory, etc.). A process that uses objective evidence to confirm that specified requirements have been met.

HACCP management systems

consist of seven principles and use a logical methodology.

What are these seven HACCP principles?

The seven principles of HACCP are:

- Hazard Analysis Identify any Physical (P), Chemical (C), Allergenic (A) or Microbiological (M) hazards that might occur at each stage

- Critical Control Points (CCP’s) CCP’s are the stages of your process where the hazards must be controlled for the food to be safe to consume. Example: Cooking, metal detection or pasteurisation

- Critical Limit Critical limits are specified safety limits at your CCP’s, which separates acceptable (safe food) from unacceptable (unsafe food). Critical limits are usually measurable values based on the scientific finding. Example: Critical limit for cooking: 80C; Critical limit for pasteurisation = 75.5 C / 15 Seconds / Flow 17000L.

- Monitoring – Monitoring procedures would need to be established to ensure hazards are controlled at CCP’s. Such monitoring activity may involve temperature checks, visual inspection and time recording Example: Checking with a probe thermometer the internal temperature of cooked food; Automatic temperature recording with a probe (within +/- 0.05 C) / filter checks and identifying who is responsible for this (Operators & management)

- Corrective Action Corrective actions are procedures to be taken when monitoring (at CCP’s) has identified that the critical limit has been or is likely to be exceeded. Example: The act of returning cooked undercooked food to the oven (65C) to continue to cook till 80C; Immediate correction: automatic flow divert / RCA: 5 Why / Ishikawa.

- Verification This involves taking an overview of your HACCP based system to ensure it is working effectively. It is checking that the checks are already done are true and effective at controlling your hazards. Refer to company heat treatment plan (MPI HTST tables). Example: Checking the checker activity; internal audits; Activity (Check such as: temperature, holding time, filters) / Frequency (how often? Daily, weekly or monthly) / Responsibility (who? Operators & management) Verification includes, pasteuriser checks, daily log sheets checks, calibration checks, flow & valve checks and internal audits.

- Documentation and record-keeping requirements A HACCP based system must have appropriate documentation to demonstrate it is working effectively. These will usually incorporate HACCP charts, work instructions, written procedures/policies. Example: Food safety (cooking) records; Pasteuriser records, daily log sheets, calibration records both soft and hard, training records, annual flow & valve checks, internal audits and third-party audits.

HACCP Review To ensure the HACCP is working effectively, it is important to review the food safety system at regular intervals. This may be when there is a change of process, flow rate, HACCP plan or a non-compliance related to the current plan.

The slides explain how GMP and Supporting Programmes support HACCP:

About our HACCP Training

HACCP Training Content Overview

- Case study review of recent food safety breakdowns and learning.

- Introduction to legislative requirements for HACCP plans and their importance

- Supporting GMP eg. Training requirements, pest control, Illness management, Hygiene, Cleaning & Sanitising. Introduction to the

- 7 Principles of HACCP.

- Introduction to food safety hazards (Physical / foreign matter-P; Chemical & Allergenic-C, Microbiological-M Pathogenic bacteria, toxins, moulds and yeast) – Simplified, detailed and VISUAL

- HACCP as a tool for identifying and controlling potential hazards Critical Control Points (CCPs) and critical limits relevant to the workplace and department requirements

- HACCP Monitoring

- HACCP Critical Control Points – CCP

- HACCP Critical Limits

- Corrective actions to be taken if limits are exceeded. Codex 3 step methodology.

- Verification and what it includes

- Record keeping – Food Control Plans and RMPs Visual application of HACCP with videos and practical examples.

Heard about 12-14 codex Alimentarius steps and now know the 7 principles to HACCP (above), but how do the two align?

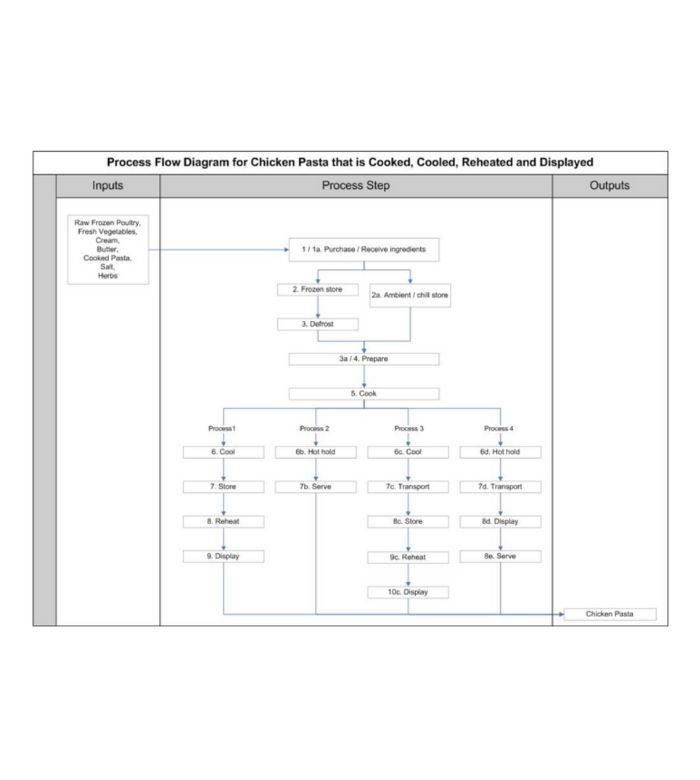

Is there a simple example of a HACCP flow chart?

Example of a HACCP table

HACCP Training Options Comparison

| HACCP Introduction/Refresher Certificate | HACCP Introduction/Refresher Certificate | Advanced HACCP Certificate |

|---|---|---|

| Duration: 1 Day | Duration: 1 Day | Duration: 2 Days |

| For: All Food Sectors | For: All Food Sectors | For: All Food Sectors |

| Suitable for: Operators | Suitable for: Supervisors | Suitable for: Senior Supervisors/HACCP Review Team Members |

| Global standardization:

Yes, standardized to Global Codex Alimentarius & GFSI |

Global standardization:

Yes, standardized to Global Codex Alimentarius & GFSI |

Global standardization:

Yes, standardized to Global Codex Alimentarius & GFSI |

| Standards comparable with other countries: | Standards comparable with other countries:

Yes, FDA Comparability Read Report |

Standards comparable with other countries:

Yes, FDA Comparability Read Report |

| Course Content: | Course Content: | Course Content: |

|

|

|

|

|

|

|

|

|

|

|

|

| Focus: Operator Monitoring & Verification, Corrective Action skills | Focus: Operator/Supervisor Monitoring & Verification, Corrective Action, Advanced RCA skills | Focus: Senior Supervisor/QA/Technical/Management: All + HACCP Plan Dev. + Review skills |

| Achievement:

HACCP Training Certificate/HACCP Refresher Certificate (if already trained) |

Achievement:

HACCP Training Certificate/HACCP Refresher Certificate (if already trained) |

Achievement:

Advanced HACCP Training Certificate |

| Who can achieve a certificate?

New Zealand & All Other Countries |

Who can achieve a certificate?

New Zealand & All Other Countries |

Who can achieve a certificate?

New Zealand & All Other Countries |

| Additional option: Only for currently employed people working in New Zealand Food Companies | Additional option: Only for currently employed people working in New Zealand Food Companies | Additional option: Only for currently employed people working in New Zealand Food Companies |

| Additional cost?

Yes (for on-job assessor time + NZQA Admin.) |

Additional cost?

Yes (for on-job assessor time + NZQA Admin.) |

Additional cost?

Yes (for on-job assessor time + NZQA Admin.) |

| HACCP Training NZ | HACCP Training NZ | HACCP Training NZ |

|

|

|

| Requires: On-job verification (application of learning back on-job) | Requires: On-job verification (application of learning back on-job) | Requires: On-job verification (application of learning back on-job) |

Applying HACCP – Part 1

The video below explains how HACCP is used to make products safe

Applying HACCP – Part 2

The video below explains how HACCP is technically applied to build a HACCP Plan

Some of the Companies & Brands Food Safe works with

Case study examples about how HACCP training is successfully applied in companies by Food Safe

Medium-sized food company case study

Large food company case study

Here’s how Food Safe Collaborates with Food Companies:

For more information, call us on +64 9 2814226 or email [email protected]

Food Safe Ltd is Accredited by the New Zealand Government + is a Category 1 NZQA-Registered PTE. Training complies with Codex Guidelines

Our training is trusted by both well known New Zealand and Global food companies and heaps of small teams too!

Our training is science-based on New Zealand regulatory and globally recognised best practice including – MPI, FAO, FDA, EU

Food Safe’s advisory committee includes leading experts, quality and compliance managers, and governance experts. For even more information about Food Safe and the companies we work with, click here

Food Safe’s Training:

- Complements compliance requirements

- Is simplified and visual, and supportive of implementing learning back on-job

- Is delivered by a trained ISO 9001 & 22000 lead auditor

- It is delivered by a trainer with first-hand knowledge and experience in high

- compliance operations where Food Safe also operates, such as the meat, dairy, and seafood sector. This allows us to transfer best practice.

For more information, call us on +64 9 2814226 or email [email protected]