Targeting company constraints

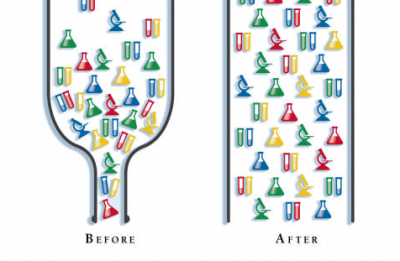

Any management system is limited in achieving more of its goals by a very small number of constraints. The challenge is to accurately and efficiently identify and act on these.

So what is a constraint and what does this mean to operations and compliance teams?

In simple terms, constraints are bottlenecks that impact efficiency in a company or business.

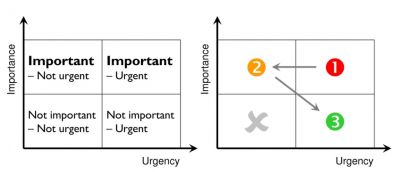

Top tips that improve operational efficiency by targeting a company’s constraints:

- Leverage technology solutions such as reminders (priority to-do lists), Google-shared documents, Face Time and promote stand-up meetings

- Reduce unnecessary multitasking that is not adding value

- Dedicate windows for just emails and telephone calls

- Delegate work to direct reports where ever possible

- Limit the number of open tasks to direct reports to just 3 at a time

- Reward efficiency and candor, targeting continuous improvement with an eye on preventative actions

- Allow for staggered breaks and flexible working for the team to get to these goals faster

Why target a constrain, is there really an opportunity for improvement, and could we do things better?

A review of the OECD GDP statistics shows that some countries track below average.

- OECD average: 37k

- GDP: New Zealand 30k

Source: OECD Productivity Commission Statistics

So what does a below-average result mean to senior management across the globe?

This means there’s efficiency still to be gained (GDP/Hour worked) and choosing a smart solutions provider such as Food Safe gets you to your goal even faster.

So what is the basic premise of constraint theory?

The approach (when looking for bottlenecks) is to move beyond machinery and widgets to include:

- People and management who are the ultimate constraint

- Question all assumptions in a company, as this could be holding you back

So what are some examples of the assumption that do not fully consider constraints within a business and hence counter-intuitive?

- Lots of multi-tasking and being really busy is always good

- The market is limited

- Extra current capacity in the system (such as a team member with time on his/her hands) should be viewed an added labour cost, and cut

When we recruit team members, we are targeting multi-tasking skills, is there a way to convince us and measure the inefficiency of too much multi-tasking?

Yes, there are exercises such as the ones below, can quantify task loads.

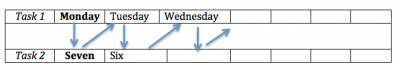

Exercise one:

Attempt two simultaneous tasks below. Fill out the names of the days of the week (Monday to Sunday) while also simultaneously writing down tasks seven to one.

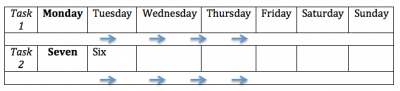

Exercise two:

Attempt two focused tasks one after another below. First, fill out just the names of the days of the week (Monday to Sunday) then proceed to count down from seven to one.

Generally speaking, exercise 1 doing two tasks in tandem would take more time than doing the same two tasks individually and one after another (exercise 2).

So what can you learn from such exercises?

- If you are recruiting, focus on a new team member’s ability to prioritize, assess risks, and ID opportunity

- On average, multitasking takes more time than focusing on a single task, one at a time, so be aware of this for your own work or when delegating

- Approximately 30 percent more efficiency/time, can be gained with proper prioritizing techniques

- Only target multiple tasks that add value, and delegate the rest thoughtfully

What are even more tips to maximize efficiency?

- Put pressure on the team to find root causes to challenges and reward preventative actions

- Book meeting rooms for uninterrupted work sessions to catch-up with current tasks

- Delegate turns at being gatekeepers to free up team time if this is holding you back

- Identify things you should not be doing today

- Cancel or freeze some of the open projects till the current ones are complete

So what can we take out from the theory of constraints to improve our business efficiency?

- Empower management with targeted training and practical tools

- Synchronize goals amongst all departments. For example: Get the Sales team, compliance managers, food technologists, and operations management to co-ordinate goals for a new product/s, compliance requirements, and cycle times

- Build-in extra man-hours in budgets and outsource time-consuming tasks

- Where possible keep the big picture in everyone’s sights and KPIs (including inventory) levels should focus on the product with the highest returns not just on revenue

- When things are tracking well, don’t let inertia become the constraint of the system

Can manufacturing companies afford to be complacent?

No, manufacturing companies and all management cannot afford to be complacent.

Under FSSC 22000 & ISO performance criteria:

8.5.1 Top management shall ensure that the organization continually improves the effectiveness of the management system

Continuous improvement is also the cornerstone of any company with global ambitions and with an eye on long-term sustainability, so there are added benefits.

Why partner with Food Safe?

- We are experts with simplifying useful learning, saving clients even more time, with a proven track record.

- We are one of the only New Zealand companies that get both Compliance and Operations, and we are able to customize this to your company needs

- We are able to build in continuous improvement and competitive manufacture type skills into existing compliance training, further optimizing your company’s resources

- Our internal audit and intuitive solutions can free up to 30 percent of your compliance management team’s time

- Through skills-based training, we can assist with thoughtful prioritization tips, tools, and apps that make your operations more efficient

- All our current advanced training programmes include Root Cause Analysis tools such as Ishikawa and applying 5 Why methodology; as well as continuous improvement tools such as lean and pre-requisite technique (PrT) identification and action lists, using real case studies and practical exercises in training.

Call us on 0800 003097 or email us at [email protected]

This blog is based on Food Safe’s experience and learning from multiple projects it has executed across the manufacturing sector combined with elements of a lecture by John Tripp, a global TOC expert, and coach currently visiting New Zealand to assist businesses.