Dryer Safety and Combustible Dust Explosion Safety Training for the dairy industry as well as for food, sugar processing, and low LEL agriculture flour handling companies.

Course Cost: POA

Dryer Safety and Dust Explosion Training

This combustible dust explosion training is for the dairy industry as well as food, sugar, low LEL agriculture, flour and grain processing companies. It is designed for operators and learners in New Zealand, Australia, EU, USA & Asia who require training to meet specific regulatory safety standards and company’s own Occupational Health & Safety Management System (OHSMS) requirements.

- Course duration: 1/2 – 1 Day

- Delivery options: LIVE Online via Zoom or in-person at company site

- Training by: A qualified ISO 22000 and ISO 9001 Lead Auditor with over 30 years’ experience in the food industry, including 15 years specialising in the dairy sector and high-risk manufacturing environments

- Provider Quality Assurance: NZQA-registered PTE

- Our practical, inclusive approach provides learners with:

✅ Clear, easy-to-follow training for all skill levels

✅ Convenience & flexibility (am & pm sessions)

✅ Practical, job-ready skills they can apply immediately

✅ An understanding of Work Safe / Safe Work Australia and FENZ / AFAC auditor requirements

Learners gain:

✅ NZQA Unit Standard Certificate of Achievement (as applicable)

✅ Certificate of Attendance Training based on NZQA Unit Standard (as applicable)

Our training helps global companies meet the requirements for:

- New Zealand Government – Work Safe – Code of Practice

- Australia IEC 60079-31: DIP (Dust-Excluding Ignition Proof)

- Australia AS/NZS 2430.3.4:2004: D&M of Dust & Fume Extraction Systems

- US Government: Combustible Dusts – OSHA 7120 & NFPA 654

- European Union: ATEX Directives (2014/34/EU and 2014/30/EU)

- ISO 45001 – Occupational Health & Safety Management System – OHSMS

- ISO 31000 – Risk Management

Course Options

- Option 1 (1/2 day training) – Dryer & Dust Explosion Training (non-unit standard). Also works well as a refresher.

- On completion, learners will gain:

- Certificate of Attendance based on Unit Standard 16311

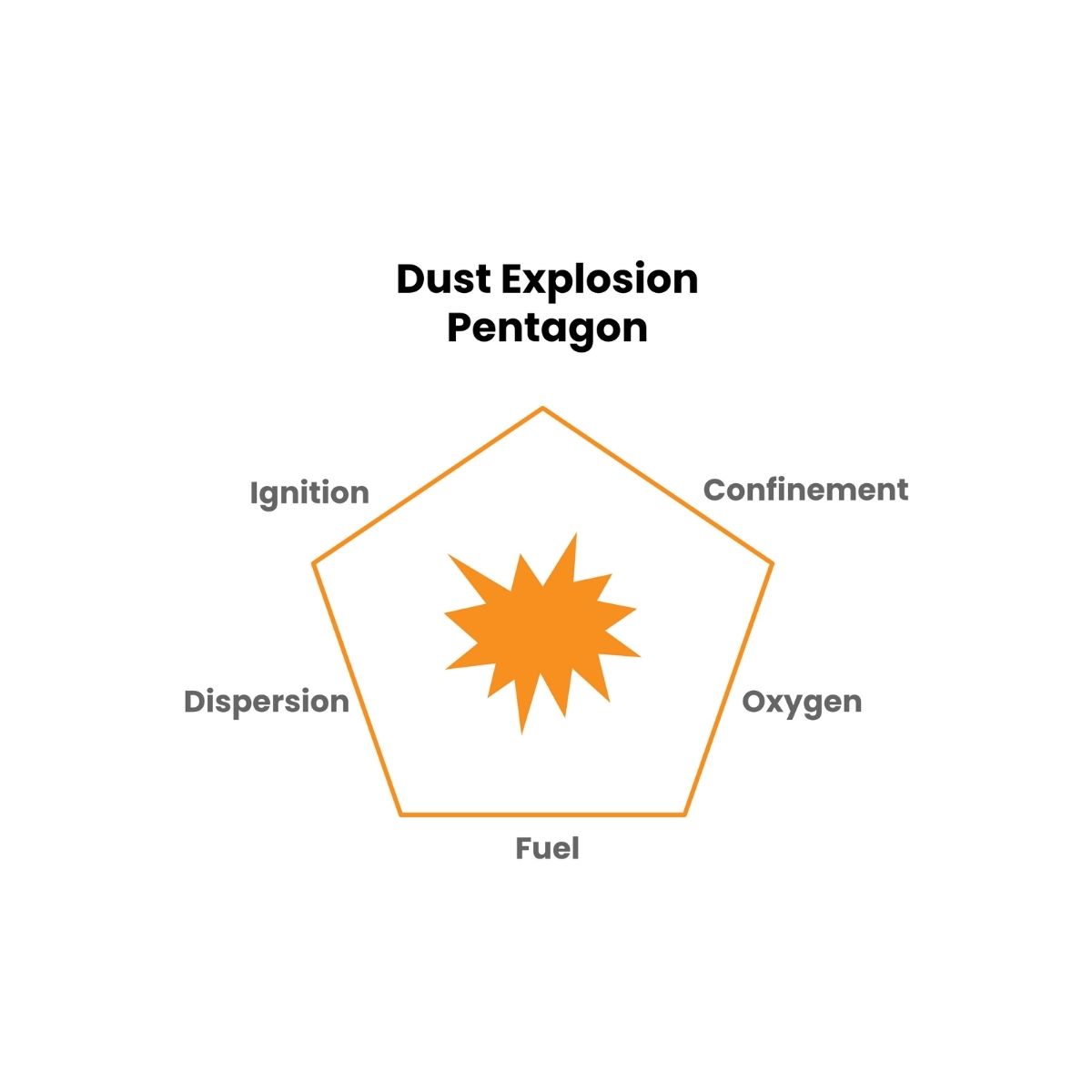

- A practical understanding of dust explosion (with a demonstration of the explosion pentagon)

- Knowledge across all food sectors & geographic regions

- This options offers learning convenience & flexibility (am & pm sessions)

- On completion, learners will gain:

- Option 2 (1-day training) – Dryer & Dust Explosion Training (unit standard).

- On completion, learners gain:

- NZQA Unit Standard 16311 Certificate of Achievement

- A practical understanding of dust explosion (with a demonstration of the explosion pentagon)

- NZQA Credits 5, Level 4 (registered with NZQA on completion) – NZ Dairy only

- On completion, learners gain:

Pre-work: Not required for either option.

Course Content

- Combustible Dust Explosion – Case Study Reviews

- Work Safe & Safe Work Australia, Approved Code of Practices & FENZ and AFAC – Requirements

- Prevention of fires and dust explosions in a processing operation

- Fire triangle & explosion pentagram (required for a fire/explosion to occur)

- Dust-to-air ratios and what this means in simple terms

- Explosive limits for different powders

- Minimum ignition temperature for powders

- Causes of fires and dust explosions in a processing operation.

- Potential sources of ignition to be managed include:

- Self-heating: hot surfaces, friction, mechanical sparks, electrical energy, electrostatic discharges, powder dags.

- Managing conditions that could lead to explosive dust clouds

- Control methods & preventing sources of potential ignition

- Methods of preventing fires and dust explosions in a processing operation.

- Plant checks for safe and unsafe conditions, & corrective action, including:

- Pre-start, correct nozzle or disk atomiser assembly (if applicable – relates to dairy dust explosion)

- Hourly monitoring, daily shift checks, shift handover, shut-down or plant-on-water checks, pre and post cleaning-in-place, permit to work, carbon dioxide, and explosion suppression bottles

- The purpose of protection systems such as:

- Explosion venting, deluge/sprinkler systems, fire detection, extinguishers & explosion suppression

- Fire and explosion protection systems access rules (ATEX food industry zoning, if applicable)

- The indicators and responses to impending fires in a processing operation.

Course Content Depth: The course content listed in both options is similar.

- In the case of option 1, topics will be covered as needed, and learners will not be required to complete a candidate book.

- In the case of option 2 (unit standard training), topics will be covered in greater depth, and learners will be required to complete a candidate book in accordance with NZQA requirements.

Optional value-added competency knowledge:

We provide Dairy, ATEX food industry, and grain mill safety-conscious companies with the option to customise training even further, enhancing operator understanding by incorporating the company’s own content.

- H&S Risk Matrix

- Internal Performance Framework reference (example: risk placement of powder explosions within the Internal Strategic Risk Management Plan – towards ‘Best in Class Operations‘)

- KPI metrics on H&S (used for reporting about Operational Excellence)

- Site-specific information about:

- Risk zones and what powder is made where (skim milk, whole milk powder, and nutritional powders), as the minimum ignition temperatures for these vary across products

- Product lines and plant layout, suppression bottles.

- Inside towers: dryers, vibrating fluid beds, cyclones, baghouses, explosion venting panels

- Temperature sensors, CO detectors, optical detectors, CO, C02, temperature, pressure sensor alert thresholds (if unique to site)

- Standard Operating Procedures:

- Permit-to-work for Hot Work, Job Safety Analysis (JSA) templates/examples, nozzle or atomiser maintenance, and explosion suppression check, shift handover (H&S related), plant-on-water, pre-/post-CIP check

- Technical SOPs for:

- Arming/disarming protection systems, manual isolation protocols, emergency evacuation, and deluge system

This SOP reinforcement & understanding at training helps elevate why some routine checks done regularly are critical for safe plant operations, minimising the risk from assumptions and confirmation bias.

Primary & Secondary Explosions

Suitable for

- Processing and Dryer Operators

- Engineers and preventative maintenance teams

- Health & Safety and OHSMS – Occupational Health & Safety Management System teams

- Senior operators, Team leaders & Supervisors

- Health & Safety Managers

- GM Risk and Risk Managers of Strategic Risk & Insurable Risk Profiling

- Occupational Health & Safety Auditors and Verifiers

About Food Safe

Food Safe Ltd is proud to be a Category 1 NZQA-Registered PTE. Our training helps companies comply with New Zealand’s and global safety audit requirements.

Our training is trusted by both well-known New Zealand and Global food companies, as well as numerous small teams.

Our training is science-based on New Zealand regulatory and globally recognised best practice – MPI, FAO, FDA, EU, including NZ Work Safe, Australia IEC 60079-31: DIP and AS/NZS 2430.3.4:2004, US OSHA 7120 & NFPA 654, EU ATEX (2014/34/EU and 2014/30/EU) plus ISO 45001 OHSMS and ISO 31000

Food Safe’s advisory committee includes leading experts, quality and compliance managers, and governance experts. For even more information about Food Safe and the companies we work with, click here

Why choose us for your training?

- Complements compliance requirements, minimising H&S risk

- Approaches training differently, and because of that, we’ve purpose-built our training courses in a fundamentally different way, focused on what’s best for you!

- Is engaging, simplified, and visual – designed to support real-world application on the job, backed by over 1,000 five-star trainee reviews.

- Is delivered by a qualified ISO 22000 and ISO 9001 Lead Auditor with over 30 years’ experience in the food industry, including 15 years specialising in the dairy sector and high-risk manufacturing environments.

- Is delivered by a trainer with firsthand knowledge and experience in global high-compliance operations, such as the dairy, pharmaceuticals, food, sugar, agriculture, grain & flour handling companies where Food Safe operates. This allows us to transfer best practices.

- Is externally reviewed and benchmarked by NZQA against global best practices to ensure excellence in delivery and outcomes.

HOW IT WORKS

How we work with companies

120

1000

100

FAQs

What is combustible dust, and why is it dangerous?

Combustible dust is any fine particulate that can ignite or explode when suspended in air. It’s dangerous because even small quantities can cause catastrophic explosions in enclosed areas.

Which industries are most at risk of combustible dust explosions?

Industries at high risk include dairy processing, grain handling, food manufacturing, sugar refineries, flour mills, agricultural storage, and pharmaceutical powder production.

What are the most common sources of combustible dust?

Common dusts include milk powder, sugar, starch, flour, grain, cereal dust, cornstarch, wood dust, plastic resins, and pharmaceutical excipients like lactose or cellulose.

How can I identify combustible dust hazards in my facility?

Conduct a Dust Hazard Analysis (DHA), test for explosibility, assess ignition sources, and classify explosion zones using standards like NFPA 652, NFPA 654, and ATEX 2014/34/EU.

What standards regulate combustible dust explosions in food and agri sectors?

Key standards include OSHA 7120, NFPA 654, ISO 45001, ISO 31000, IEC 60079-31, ATEX Directives, and local safety codes such as AS/NZS 60079.10.2.

What is a Dust Hazard Analysis (DHA)?

A DHA is a systematic review to identify and assess combustible dust hazards, required under NFPA 652 and NFPA 654, and recommended for ISO 45001-compliant systems.

Is dairy powder explosive?

Yes. Dried milk powders are combustible and can explode under certain conditions—especially in environments such as spray drying, fluid bed, or pneumatic conveying.

What is the minimum ignition energy (MIE) for flour, sugar, or starch dust?

MIE varies by dust type but is typically between 10–50 mJ. For example, wheat flour is ~30 mJ, cornstarch ~40 mJ, and lactose (pharma-grade) ~35 mJ.

How do I comply with ATEX and IEC dust safety standards?

Ensure proper area classification (Zone 20/21/22), equipment marked Ex t/DIP compliant (IEC 60079-31), and documentation per ATEX 2014/34/EU.

Can sugar dust explode in processing plants?

Absolutely. Sugar dust has a low ignition temperature and has caused multiple historic explosions. Strict housekeeping, ventilation, and spark control are essential.

What explosion risks exist in flour milling or grain handling?

Dust from wheat, maize, oats, and soy can accumulate in conveyors, elevators, or silos, posing ignition risks due to friction, heat, or static discharge.

What are the top ignition sources in food and grain plants?

Static electricity, overheated bearings, sparks, welding, electrical faults, and friction from conveyors or motors are leading ignition sources.

What is Ex t protection for dust explosion zones?

Ex t (per IEC 60079-31) means equipment is built with dust-tight enclosures to prevent dust ingress and control surface temperatures that could cause ignition.

How often should combustible dust training be conducted?

Annual refresher training is best practice, especially for high-risk areas such as spray drying, bulk powder handling, or baghouse operations.

Is combustible dust a legal workplace hazard?

Yes. Many countries classify combustible dust as a known hazard requiring control under workplace safety laws, e.g., OSHA (USA), Safe Work Australia, WorkSafe NZ, and ATEX (EU).

What is the difference between HACCP and DHA?

HACCP focuses on food safety, while DHA assesses the physical explosion risk from dust. Both are vital but target different risk domains.

How can I minimise the risk of dust explosions in my facility?

Improve ventilation, maintain housekeeping, eliminate ignition sources, install explosion venting or suppression systems, and implement a documented DHA and training program.

Do pharmaceutical powders pose an explosion risk?

Yes. Powders like lactose, starch, and certain APIs can be explosive. Granulation and tablet coating zones should be assessed for dust risk.

What cleaning methods reduce dust buildup in plants?

Use central vacuum systems (not compressed air), anti-static tools, and regularly perform deep cleans. Also, monitor horizontal surfaces for dust accumulation.

What is Zone 20, Zone 21, and Zone 22 in dust classification?

Zone 20: Dust is present continuously

Zone 21: Likely during normal operations

Zone 22: Rare or short-term presence

What is IEC 60079‑31 / AS NZS 60079.31 “Ex t” – Dust‑Excluding Ignition‑Proof (DIP)?

This standard defines requirements for protection by enclosure “t” (Ex t), ensuring dust cannot enter electrical equipment in hazardous dust atmospheres (Group III). It includes ingress protection levels, surface temperature limits, and testing protocols. Used with IEC 60079-0 for general Ex equipment.

What is AS/NZS 2430.3.4:2004?

This legacy standard provides guidance for classifying hazardous areas involving dust and fume extraction. Although replaced by AS/NZS 60079.10.1, it offers valuable example-based insights for zoning based on dust dispersion, sources, and concentrations.

What is OSHA 7120 and NFPA 654?

OSHA 7120 is a training course that teaches recognition of combustible dust hazards and prevention strategies. NFPA 654 is the key U.S. standard requiring DHA, engineering and administrative controls, ignition source management, explosion mitigation, and staff training.

What are the ATEX Directives 2014/34/EU & 1999/92/EC?

ATEX 2014/34/EU regulates equipment used in explosive atmospheres, including dust environments, requiring CE certification and Ex markings. ATEX 1999/92/EC governs workplace safety: area zoning, equipment selection, and risk control to protect workers.

What is ISO 45001?

ISO 45001 is the international OHS management standard. It ensures that organisations implement systems for identifying dust hazards, engaging workers, managing change, conducting incident reviews, and continuous improvement of safety performance.

What is ISO 31000?

ISO 31000 outlines a risk management framework. It supports identification, analysis, treatment, and communication of risks, including DHA integration into operational planning and OHS governance (complementing ISO 45001).

How do these standards and frameworks fit together?

|

Standard / Directive |

Role in Program |

Key Components |

|

IEC 60079‑31 (AS/NZS) |

Equipment protection (Ex t / DIP) |

Enclosures, ingress protection, dust-tight rating |

|

AS/NZS 2430.3.4 (legacy) |

Zoning guidance |

Hazardous dust area classification examples |

|

OSHA 7120 & NFPA 654 |

U.S. hazard training & standards |

DHA, engineering controls, training, housekeeping |

|

ATEX 2014/34/EU & 99/92/EC |

EU equipment & workplace safety |

Certification, zone classification, worker protection |

|

ISO 45001 |

OHS management system |

Leadership, culture, and emergency preparedness |

|

ISO 31000 |

Risk management integration |

DHA alignment, risk review, and communication |

Dust Explosion Prevention: Unit Standard 16311

Course content

Describe the prevention of fires and dust explosions in a dairy processing operation.

This theory-based unit standard is for individuals involved in milk product processing within a dairy processing operation. People credited with this unit standard are able to describe:

- Causes of fires and dust explosions in a processing operation;

- Methods of preventing fires and dust explosions in a processing operation;

- Fire and explosion protection systems, and access rules; and

- Indicators and responses to impending fires in a processing operation.

Dryer Safety Unit Standard 4831

Course content

Describe evaporation and spray drying of dairy products in a dairy processing operation.

This theory-based entry-level unit standard is for individuals involved in milk product processing within a dairy processing operation. People credited with this unit standard can describe:

- The purposes of evaporation and spray drying, and common uses of the main classes of spray-dried dairy products in processing

- The main components and controls of the evaporation process in a processing operation

- The main components and controls of spray drying in a processing operation; and

- The properties and company food safety requirements of spray-dried dairy products in a processing operation.

NZQA Unit Standard 16311

Describe the prevention of fires and dust explosions in a dairy processing operation

NZQA level 4, Credits 5

People credited with this unit standard are able to describe: the causes of fires and dust explosions; methods of preventing fires and dust explosions; fire and explosion protection systems, and access rules; and indicators and responses to impending fires, in a dairy processing operation.

NZQA Unit Standard 4831

Describe the evaporation and spray drying of dairy products in a dairy processing operation

NZQA level 3, Credits 5

People credited with this unit standard can describe: the purposes of evaporation and spray drying, and common uses of the main classes of spray dried dairy products; the main components and controls of the evaporation process; the main components and controls of spray drying; and the properties and company food safety requirements of spray dried dairy products, in a dairy processing operation.

Approved Code of Practice

Combustible Dust Handling Guide

Additional information

Grain Mill Safety: Preventing Fires and Explosions

Grain milling facilities are inherently at risk for dust explosions and fires due to the presence of fine, combustible grain particles suspended in air. Even small ignition sources can lead to catastrophic outcomes if safety controls are not in place.

Key Hazards in Grain Milling Operations

- Accumulation of combustible dust (wheat, maize, soy, etc.) on horizontal surfaces and equipment

- Ignition sources such as overheated bearings, static discharge, electrical sparks

- Conveyors, elevators, sifters generating friction or trapping dust

- Confined spaces such as silos and mixers increasing explosion severity

Recommended Safety Controls

- Conduct a Dust Hazard Analysis (DHA) in accordance with NFPA 652

- Install explosion relief vents, suppression, and isolation systems

- Use ATEX-certified equipment in dust zones (Zone 20, 21, 22)

- Ensure static grounding and bonding of equipment and metal structures

- Implement strict housekeeping routines and dust collection systems

- Train staff on dust awareness, emergency response, and shutdown procedures

Common Grain Mill Risk Areas

| Area | Explosion Risk |

|---|---|

| Bucket elevators | High-speed belt friction, enclosed dust atmosphere |

| Hammer mills & sifters | Dust generation + metal contact spark hazard |

| Storage silos | Zone 20 conditions, risk of dust layering & ignition |

| Pneumatic conveying lines | Static charge buildup and pressure surge ignition |

Combustible Powder Handling: Risk Reduction Strategies

Combustible powders such as starches, sugars, spices, milk powder, and pharmaceutical excipients can ignite when dispersed in air. The risk increases in enclosed spaces where the dust cloud concentration exceeds the Minimum Explosive Concentration (MEC).

Critical Properties of Combustible Powders

| Property | Typical Range | Relevance |

|---|---|---|

| Minimum Ignition Energy (MIE) | 10–50 mJ | Lower values = higher explosion risk |

| Minimum Explosive Concentration (MEC) | 10–300 g/m³ | Critical for airborne dust accumulation |

| Maximum Pressure (Pmax) | 6–12 bar | Explosion force potential |

| Dust Cloud Ignition Temperature | 400–600°C | Temperature needed to ignite a dust cloud |

Safe Powder Handling Practices

- Control dispersion and airborne concentration using enclosed transfer systems

- Prevent ignition sources using intrinsically safe equipment

- Use inerting systems (e.g., nitrogen blanketing) for sensitive powders

- Install real-time CO/temperature sensors in drying or conveying systems

- Conduct regular combustibility testing (MIE, MEC, Kst, etc.) on powders

- Document a combustible dust management plan under ISO 45001 or ATEX

Industries at High Risk

- Flour and cereal milling

- Dairy powder and spray drying plants

- Confectionery (sugar and cocoa powder)

- Pharmaceutical powder processing

- Spice, starch, and tea/coffee facilities

What is ATEX in the Food Industry?

ATEX refers to two European Union directives that regulate equipment and workplace safety in environments where explosive atmospheres may occur. The term “ATEX” originates from the French phrase “Atmosphères Explosibles.”

ATEX Directives

- ATEX 2014/34/EU

- Applies to equipment and protective systems used in potentially explosive atmospheres.

- Manufacturers must ensure their equipment is certified and marked for use in explosive zones (dust, gas, or vapours).

- ATEX 1999/92/EC (also called ATEX 137)

- Applies to workplace safety and employer responsibilities.

- Food processing companies must assess explosion risks, classify zones, and implement controls to protect workers.

Why Is ATEX Important in the Food Industry?

Many food powders are combustible, including:

- Milk powder

- Wheat flour

- Cornstarch

- Sugar

- Cocoa

- Soy

- Coffee dust

- Spices (e.g., chilli powder, turmeric)

When suspended in the air at specific concentrations, these powders can ignite explosively, especially within confined equipment such as dryers, mixers, or pneumatic lines.

ATEX Zoning for Dust in Food Plants

| Zone | Description | Example Locations |

|---|---|---|

| 20 | Dust is present continuously or long-term | Inside a spray dryer or silo |

| 21 | Dust is present intermittently during normal ops | Bagging lines, mixers, hoppers |

| 22 | Dust is present abnormally or for short periods | Storage rooms, under conveyors |

Each zone requires certified ATEX equipment rated for the corresponding risk level, as well as Ex tD or Ex II 3D/2D markings.

ATEX Compliance Checklist for Food Processors

Conduct an explosion risk assessment (mandatory under ATEX 1999/92/EC)

✓ Classify hazardous zones (20, 21, 22) and document them

✓ Install ATEX-certified equipment (e.g., motors, sensors, lights)

✓ Ensure all enclosures are dust-tight with appropriate surface temperature ratings (IEC 60079-31)

✓ Implement ignition source control: no sparks, friction, static, or heat buildup

✓ Use explosion relief, suppression, or isolation systems

✓ Train staff on dust hazard awareness and safe work practices

✓ Keep detailed documentation and equipment inspection records

ATEX Marking Example (For Equipment in Zone 21)

Ex II 2D Ex tD A21 IP65 T120°C

- II: Equipment group for surface industries

- 2D: Suitable for Zone 21 (Category 2 Dust)

- Ex tD: Protected by enclosure (dust-tight)

- A21: Zone 21 use

- IP65: Dust-tight and water-resistant

- T120°C: Max surface temperature

ATEX in Common Food Industry Equipment

| Equipment | ATEX Concern |

|---|---|

| Spray dryers | Internal dust buildup, ignition risk |

| Sifters/mixers | Friction, mechanical sparks |

| Pneumatic conveyors | Static electricity, confined spaces |

| Bagging/filling stations | Dust clouds + static ignition |

| Silos/hoppers | Long-term dust presence (Zone 20) |

| Dust collectors (baghouses) | High explosion risk if not maintained |

Consequences of Non-Compliance

- Fines or shutdowns by local safety authorities (WorkSafe, HSE, etc.)

- Fire or explosion resulting in injury or fatality

- Loss of production and product recall

- Insurance issues in case of loss claims

Video Resource

Companies we work with